Introducing DOWN CODEX® from Mountain Equipment

Since its inception in 2009, DOWN CODEX® has been the flagship programme for down-sourcing across the outdoor industry. Our ongoing commitment to ethical standards is reflected in our promise to eliminate live-plucking, force-feeding, and bill-trimming from the down-production process.

We ensure that only the highest quality virgin down is used in our products while also adhering to the Responsible Down Standard (RDS) for sourcing and communication.

With our individual ‘Trace My Down’ codes, users can access detailed information about the down used, giving them greater knowledge about Mountain Equipment products.

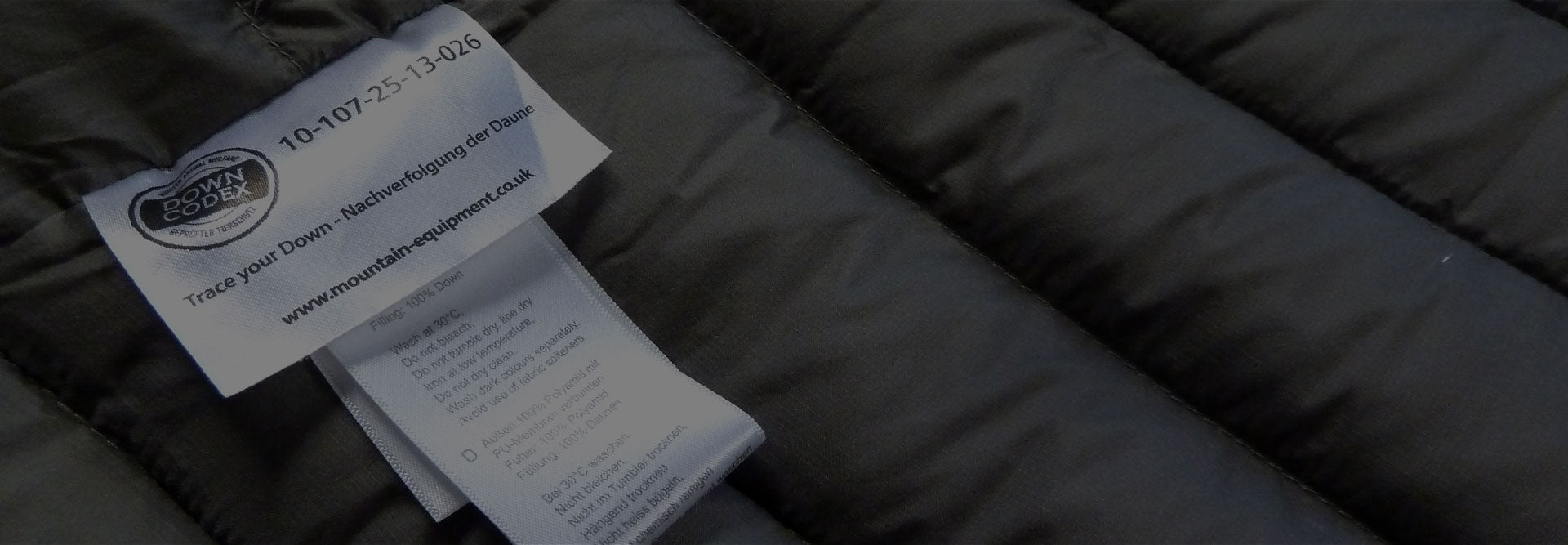

Trace Your Down

You can find your 12 Digit code printed on the DOWN CODEX® stamped label inside of your product.

Simply enter this via the link below to access to specific information relating to the down in your product.

History of DOWN CODEX®

Frequently Asked Questions

Sourcing down can be complicated. This FAQ section addresses common questions about the sourcing, sustainability, and ethical practices of our down products and supply chains.

-

What is down, and why do we use it in our products?

Down refers to the soft under feathers of waterfowl, particularly geese and ducks raised for their meat. After the birds are slaughtered, the down and flight feathers are removed, cleaned, and sorted for quality. Down is an excellent fibrous insulation as it has the highest warmth-to-weight ratio and is highly compressible and long-lasting. It is beneficial for high-performance outdoor equipment and has been used for over a century. In addition, it has been used in bedding for centuries.

-

Where do you source your down from?

We source virgin down and feathers from three different supply chains: two sources of duck down from Poland and China, and goose downis sourced from Ukraine. The Responsible Down Standard (RDS) certifies all ourvirgin down supply chains. Customers can verify the origin and quality of thedown in their products using the unique "Trace Your Down" code provided on each product.

-

What is the Responsible Down Standard (RDS)?

In 2022, Mountain Equipment incorporated the Responsible Down Standard (RDS) into its DOWN CODEX® initiative. This standard is a globally recognised third-party certification program that dictates animal welfare, and ensures a traceable chain of custody of the materials across the supply chain.

The Responsible Down Standard (RDS) certifies that the down used in products has not been obtained from live-plucked or force-fed birds, and that their welfare is maintained throughout their life.Independent certification bodies inspect the supply chain each year to ensure traceability and compliance, including farms, collectors, slaughterhouses, down processors, sewing factories, and distribution centres.

-

Why did you only implement RDS in 2022?

We were not RDS certified in the past but participated in Responsible Down Standard (RDS) working groups to share the knowledge and experience we have gained from DOWN CODEX®. With the introduction of RDS 3.0 in 2020/2021, the welfare standards between RDS and DOWN CODEX® became nearly equal. Since many of our retail partners were more familiar with RDS, we decided to become an RDS-certified brand and integrate it into our DOWN CODEX® initiative.

-

How does Mountain Equipment guarantee that no birds come to unnecessary harm?

It's important to understand that we can't provide a guarantee. Audits are conducted to evaluate and verify current conditions and processes, but they can only assess what is observed on the day of the audit. Nevertheless, we can be confident that the principles we have created and implemented through the Responsible Down Standard (RDS) and DOWN CODEX® initiative effectively reduce and manage potential risks.

-

What is the difference between an industrial supply chain and a collection-based one?

Mountain Equipment sources down from two different types of supply chains: large industrial and smaller collection-based models. Both are part of the meat industry, so the down and feathers are by-products.

In the industrial supply chain, birds usually come from large farms and are kept in barns in large numbers. They are then sent to a slaughterhouse, and the down and feather are sent to a processing plant. The operation can be a single large farm or a collection of numerous farms, depending on the size of the operation.

In a collector-based supply chain, birds are raised on small farms in small numbers (around twenty to fifty birds per flock), and they may be slaughtered on the farm or sent to local slaughterhouses. Any down taken from these birds is sold to an agent or collector who collects down and feather material from many small farms until they have enough to sell to a processor. -

Do we inspect the farms ourselves?

The farms we work with are inspected by independent third-party certification bodies, which are regulated by an accreditation body. As a certified Responsible Down Standard (RDS) brand partner, we ensure our partners meet the RDS standards.

Before becoming an RDS-certified brand partner in 2022, we used independent third parties to conduct audits on our behalf. However, our standards were not certified nor regulated by anyone but ourselves.

We occasionally visit a small representation of the farms ourselves to gain a first-hand understanding of the conditions and processes that help inform our practices. -

Is every farm inspected every year?

To put it briefly, the answer is no. The Responsible Down Standard (RDS) employs a representative sampling technique to evaluate the farms. This method involves visiting random farms in the area to create an understanding of the whole supply chain. The rationale is that there are too many individual farms supplying down and feather materials to collectors and processors, and conducting annual inspections and audits on each of them would be impractical.

-

Where does recycled down come from, and is it RDS certified?

Recycled down is obtained from consumer products, such as used duvets and pillows, that have been discarded in general waste and would end up in landfills or incinerated waste. After being cleaned, sterilised, and separated, the best quality down is used in our DOWN CYCLE® products. In contrast, the remaining lower-quality down and feathers are used in household products. As a result, it is impossible to determine the exact origin of the recycled down, making it impossible to obtain Responsible Down Standard (RDS) certification.

-

What are the alternatives to down?

Many options are available as an alternative to down, and synthetic equivalents are gradually improving. Nonetheless, nothing beats down regarding loftiness and performance in dry conditions. Mountain Equipment offers a variety of synthetically insulated products, including sleeping bags, jackets and accessories, in addition to our down products.